Call : 07971584310

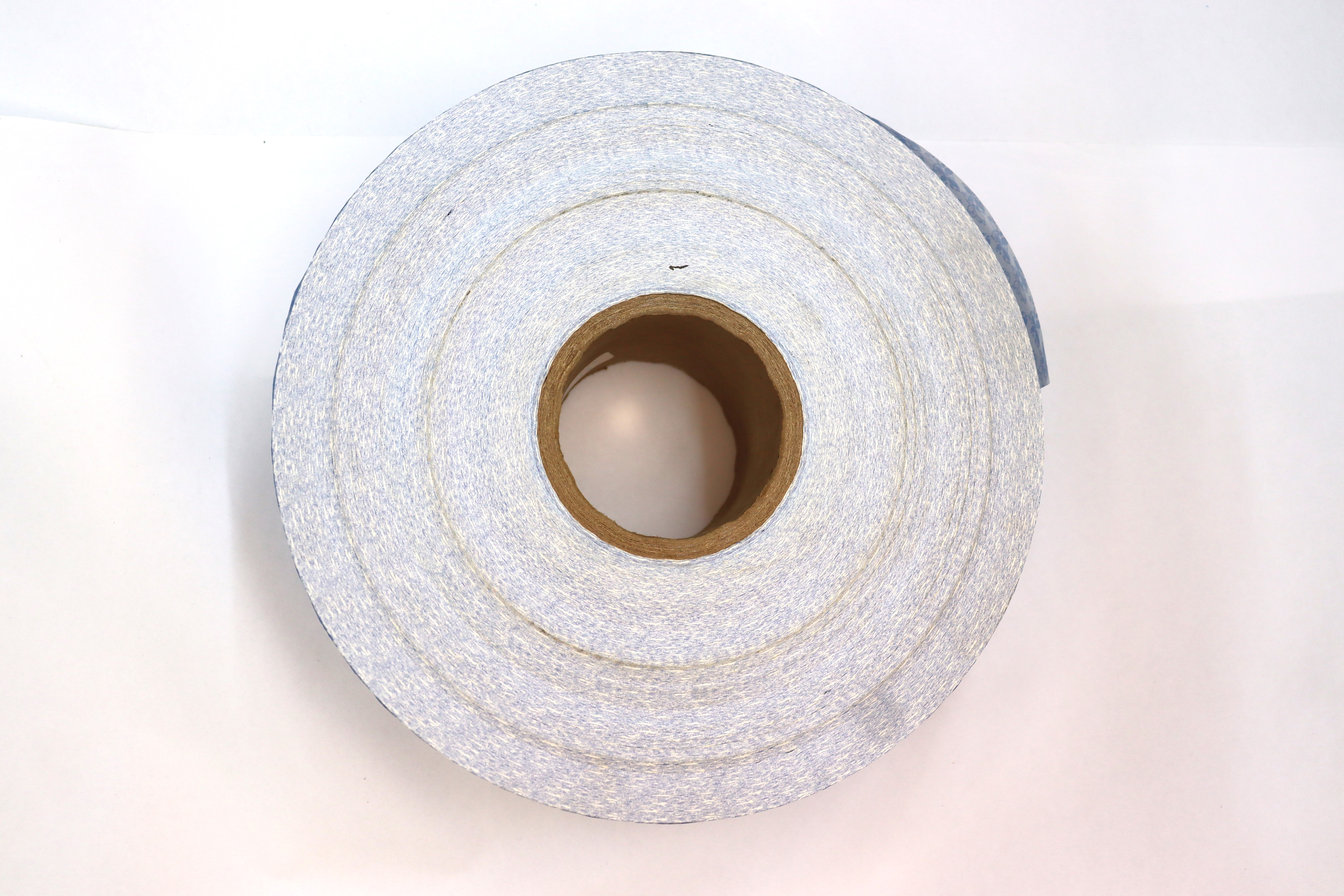

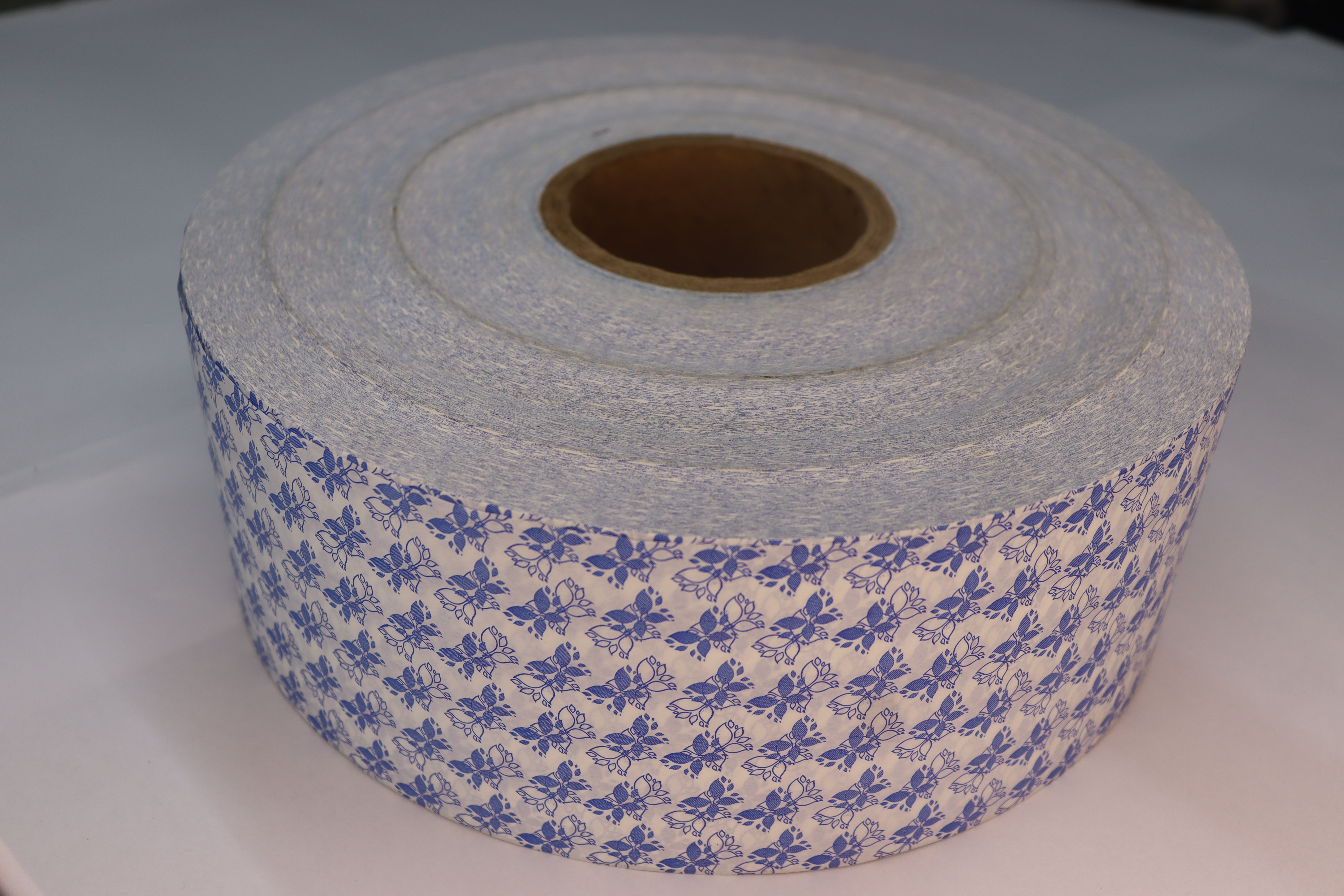

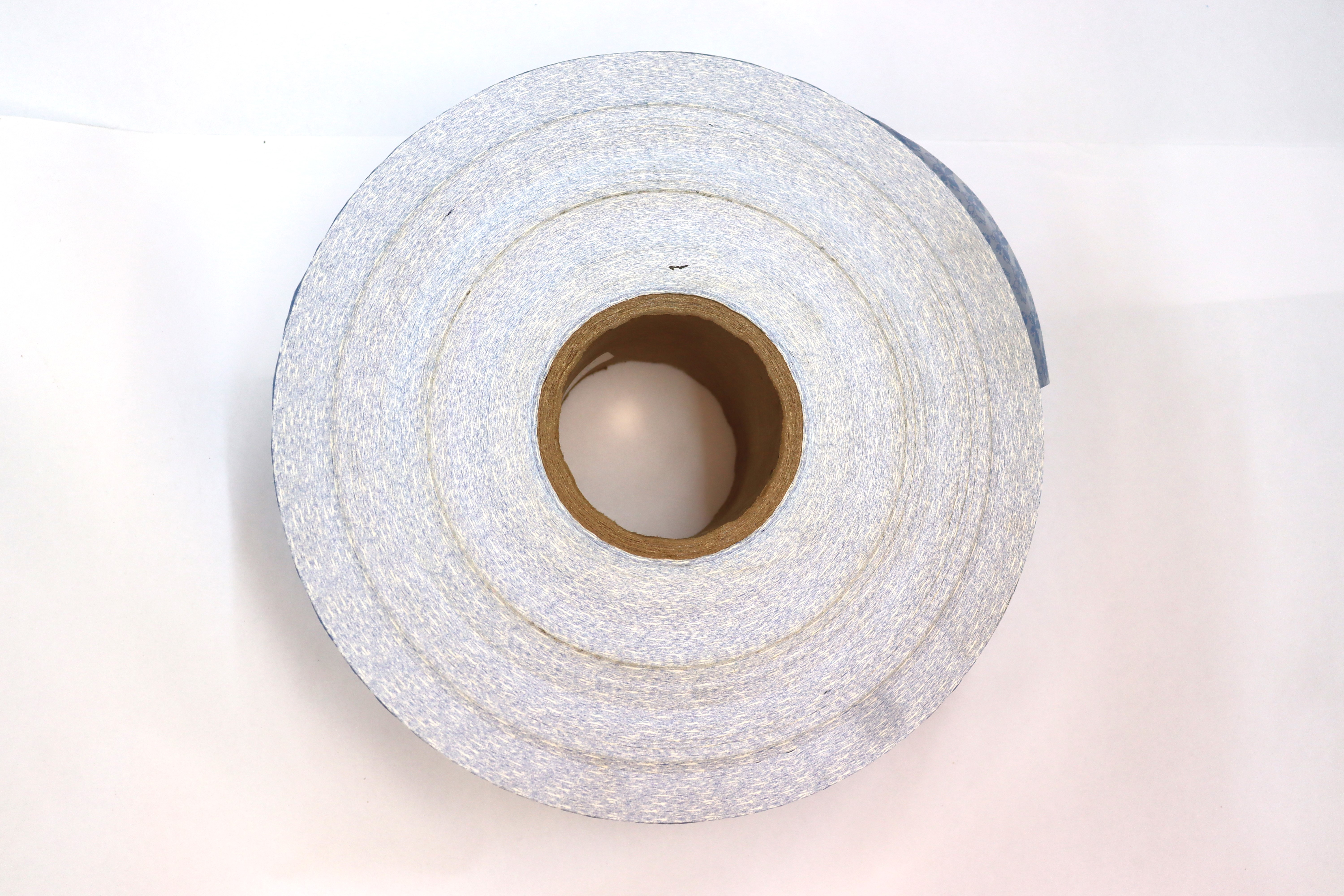

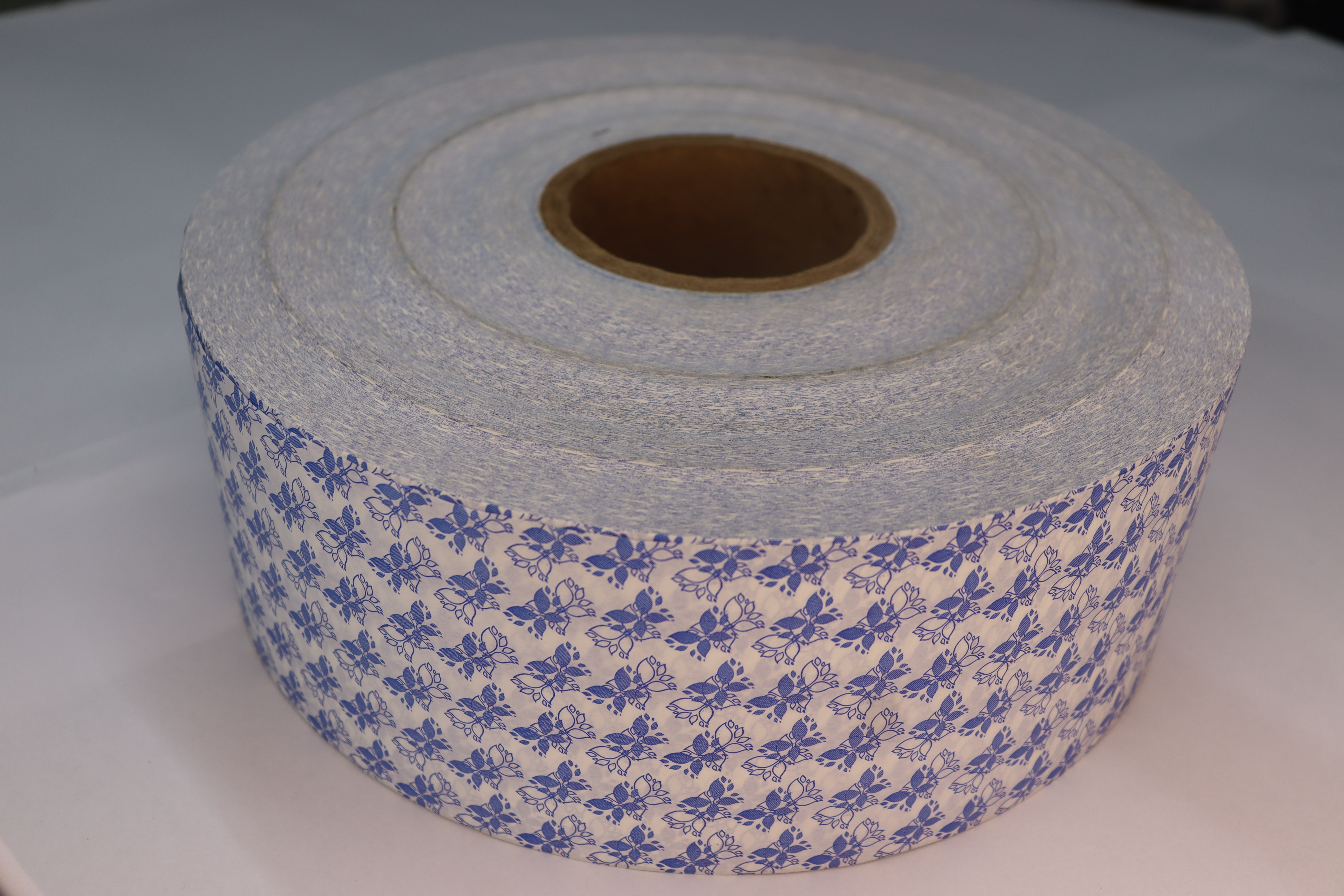

Design Printed one side coated silicon paper

177.0 INR/Piece

Product Details:

- Material Paper

- Width 24 Millimeter (mm)

- Length 24 Millimeter (mm)

- Thickness 40 Millimeter (mm)

- Size ASPER CUSTOMER REQUIREMENT

- Color White

- Warranty 1 Year

- Click to View more

X

Design Printed one side coated silicon paper Price And Quantity

- 200 Piece

- 177.0 INR/Piece

Design Printed one side coated silicon paper Product Specifications

- 24 Millimeter (mm)

- White

- For Personal Use For Business Use

- ASPER CUSTOMER REQUIREMENT

- Paper

- 1 Year

- 24 Millimeter (mm)

- 40 Millimeter (mm)

Design Printed one side coated silicon paper Trade Information

- i A e ( C ) ' v , u C a s h l ( C A D ) ' , ' C O D ) ' , a n c e ' A g a i n s t D e v e r y a s h o n D e l i v e r n A d a e ( C I ) ' ' C h e q ] [ ' y ( C ' C a s h d v A , ' C a s h i n c D

- 5000 Piece Per Month

- 7 Days

- Packing is available on sheets & rolls formats as per customer preference, packing goods packed by paper packing, taped, goni, cartoon, PVC rapper finally dispatched.

- ' A l [ l I n d i a ' ]

Product Description

Designing printed one-side coated silicon paper involves several key considerations, both for the printing process and the physical characteristics of the paper. Here's a breakdown of the design approach and the key features you should consider:

1. Paper Type:

- Base Paper: The underlying paper can be a standard or premium quality paper (e.g., kraft, woodfree, or art paper) that is coated on one side with a silicone layer.

- Coating: The silicone coating is applied to only one side of the paper, which makes that side water- and oil-resistant. It also helps the ink dry faster and remain vibrant during printing.

2. Design Layout:

- Artwork for Printing: The design should be planned for the printed side (the non-coated side). Ensure the artwork is created with appropriate resolution (300 DPI for high-quality prints). For example, logos, text, illustrations, or patterns that will appear on the printed side.

- Bleed and Margins: Include a bleed area of about 3mm to 5mm around the design to prevent any cut-offs when the paper is trimmed. Margins should be clear from text and logos to avoid cutting them off.

- Typography: Choose fonts that are legible when printed on the coated side, ensuring high contrast between the paper and the text. Dark text on light backgrounds or vice versa tends to work best.

3. Ink Compatibility:

- Ink Types: Use inks that are compatible with the silicone-coated paper (e.g., UV inks, solvent-based inks, or specific inks for coated substrates). This ensures that the ink adheres well and provides a vibrant finish.

- Drying Process: The silicone coating helps prevent ink smudging, so faster-drying inks like UV inks can be advantageous.

4. Coated vs. Uncoated Side:

- Coated Side (Silicone Coating): This side is glossy, smooth, and water-resistant, but it is not printable. However, it provides a protective layer, so ensure that your design is focused on the uncoated side.

- Uncoated Side (Printable): Focus your design on this side, which will hold the ink well and provide better color reproduction.

5. Design Elements to Consider:

- Branding: Ensure your design aligns with the branding of the product or company. Use brand colors, logos, and taglines effectively in the design.

- Color Scheme: Because the silicone coating can sometimes affect the color absorption, make sure your colors are selected to contrast well and appear vibrant.

- Pattern: Consider geometric, abstract, or floral patterns that can work well on coated paper, which will bring a glossy and high-end feel.

6. Applications:

- Packaging Designs: Silicon-coated paper is often used for packaging such as food wraps, labels, or protective liners. Ensure the design includes necessary information like product details, ingredient lists, and barcodes in the correct positions.

- Specialty Uses: It can also be used for printing high-end gift wrapping, stationery, or business cards where a glossy finish is desirable.

7. Production Process:

- Prepress: Prepare the design files in CMYK mode, as most printing uses this color model. Ensure all fonts are outlined, and images are in the correct color space.

- Printing: Depending on the quantity, offset printing or digital printing can be used. Offset printing is preferred for larger runs, while digital is ideal for small runs or prototypes.

Example Design Concept:

For a simple luxury packaging design on one-side coated silicon paper:

- Front Side (Printable Side): A gold and black logo placed centrally on a matte-black background. Elegant font choices for product description and minimalistic line art or border accents to highlight the edges.

- Back Side (Coated Side): Glossy and embossed with product-related branding elements or a company tagline to make it visually appealing.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'G1 SILICON PAPER' category

|

G K ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry