Call : 07971584310

X

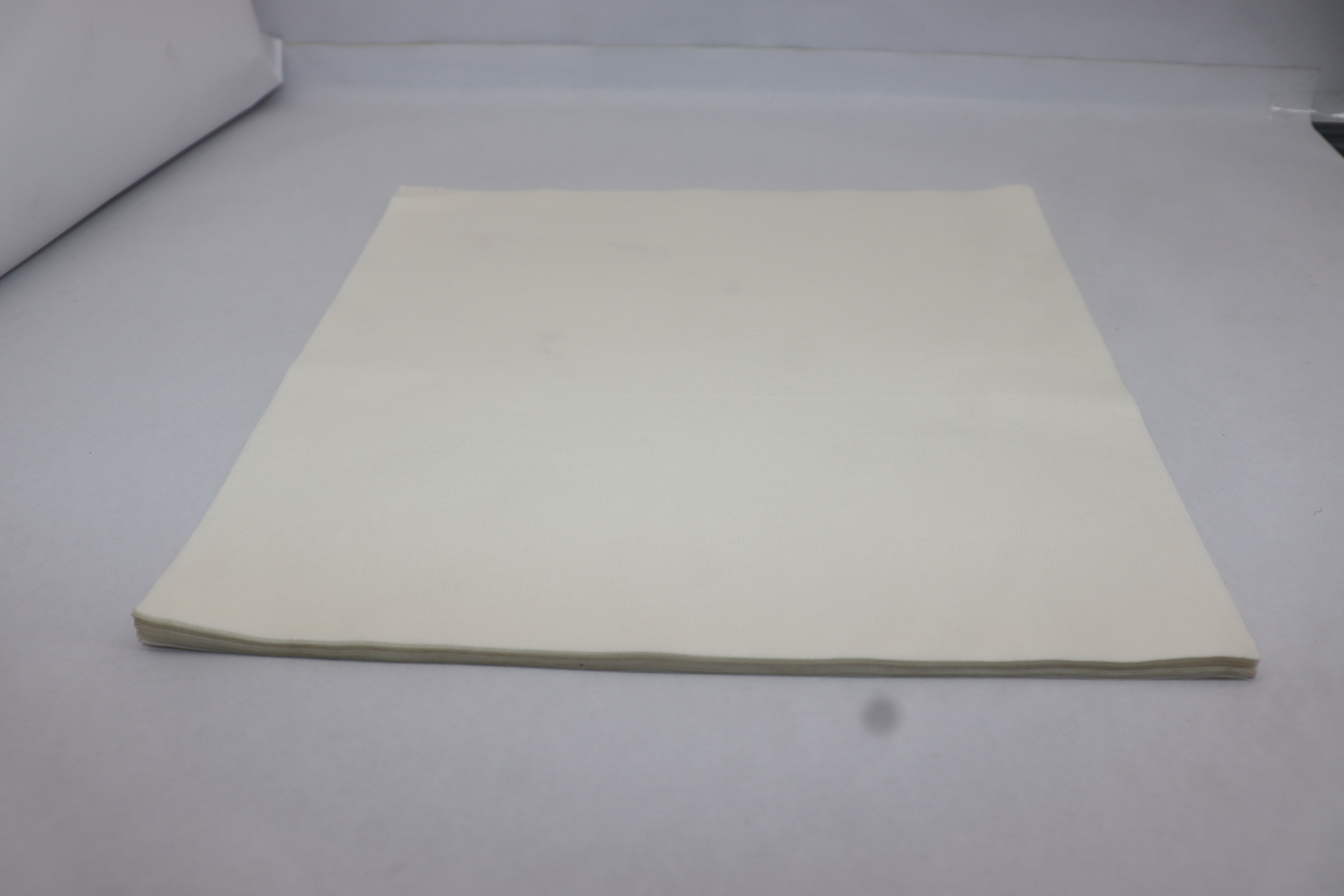

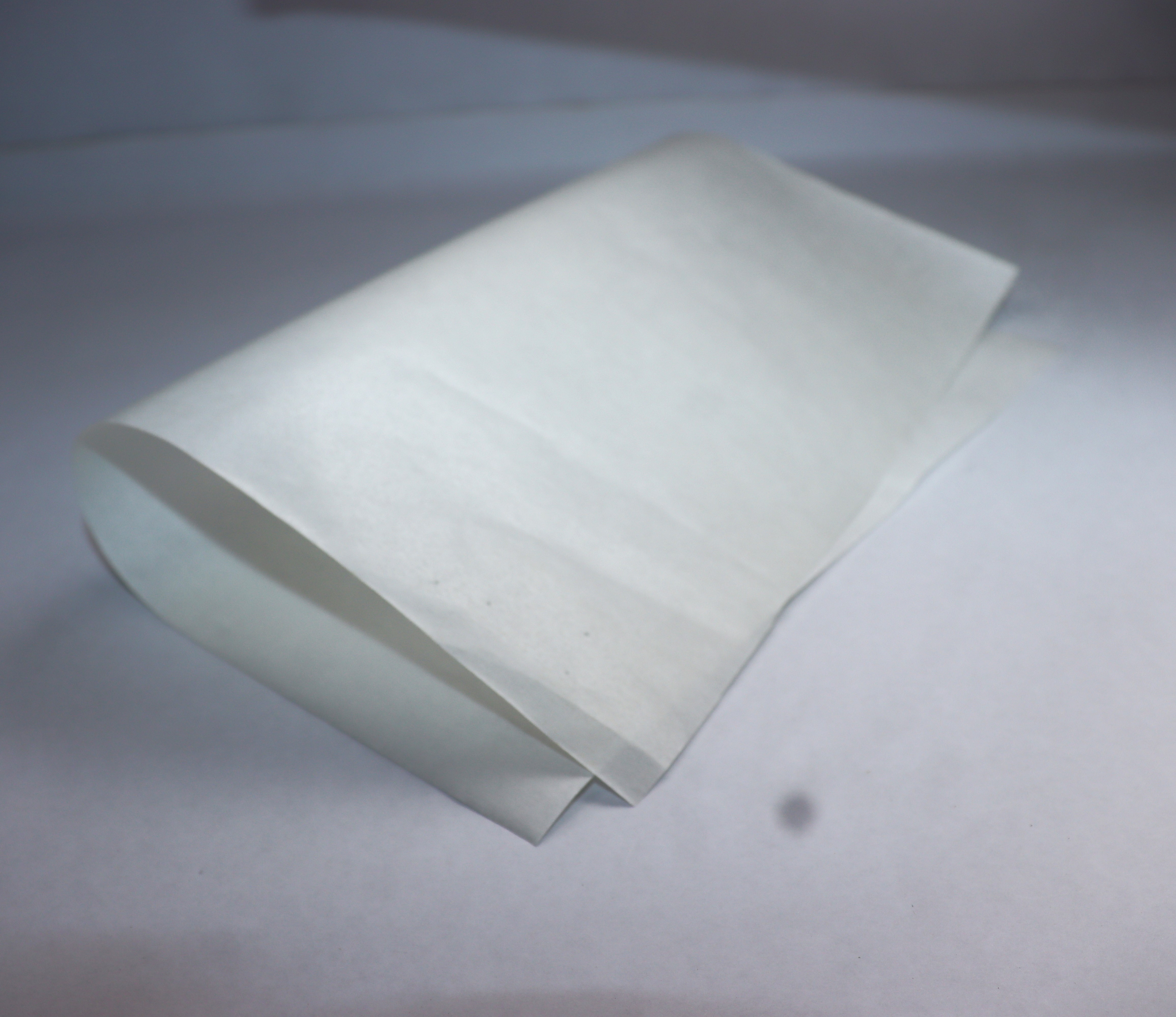

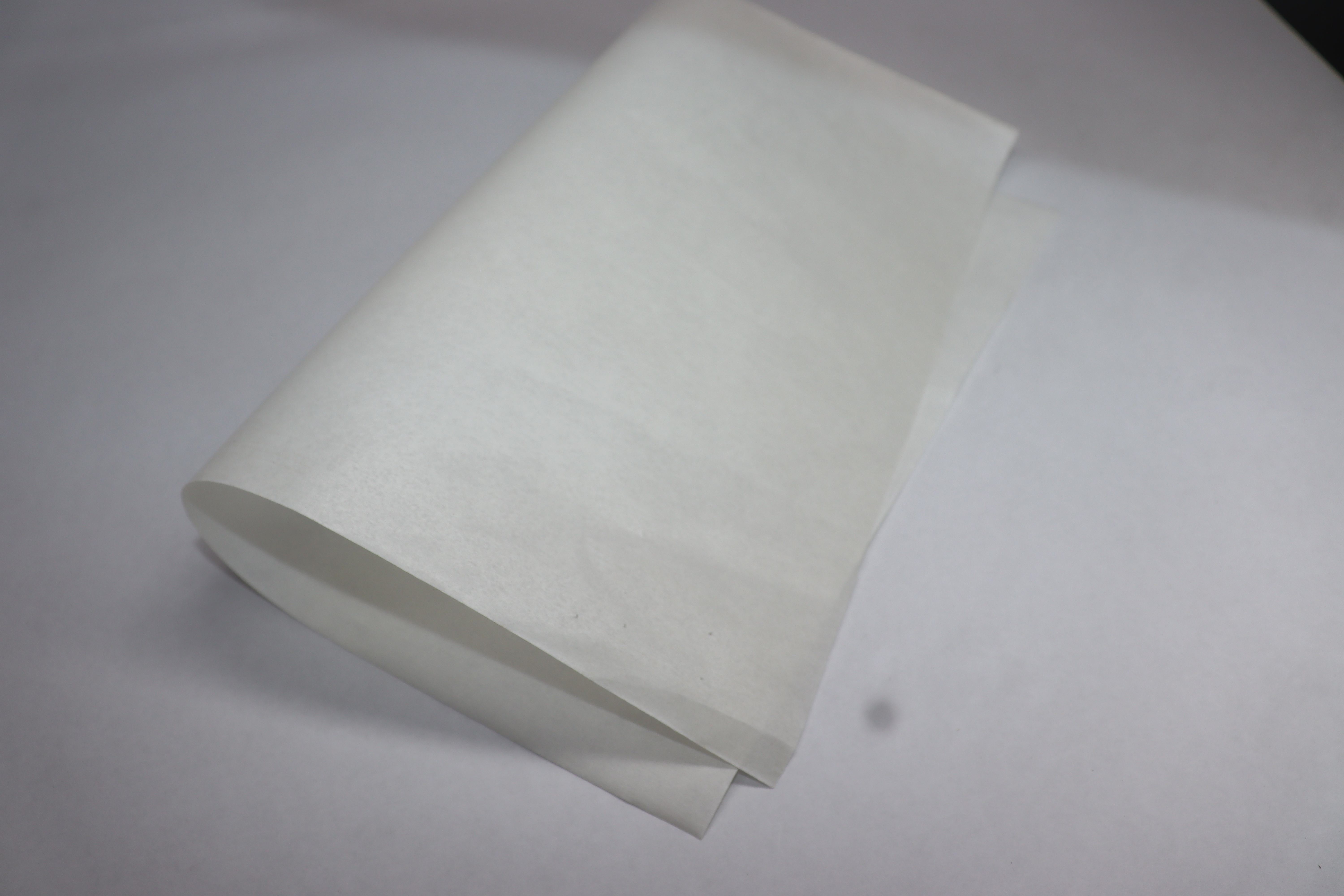

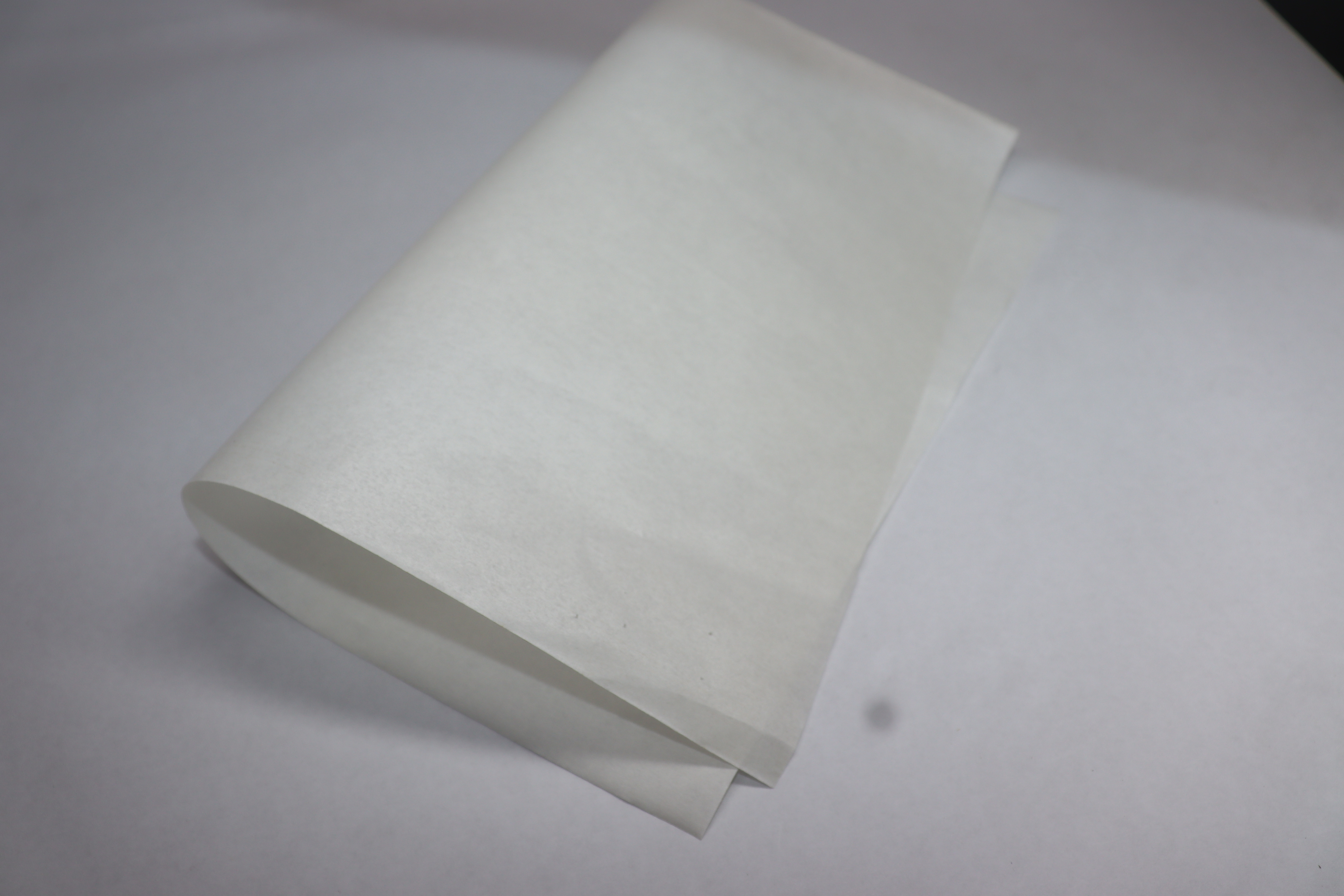

heat sealing butter paper Price And Quantity

- 200 Kilogram

- 169.0 INR

heat sealing butter paper Product Specifications

- White

heat sealing butter paper Trade Information

- Cash Against Delivery (CAD) Cash on Delivery (COD) Cash Advance (CA) Cash in Advance (CID) Cheque

- 2000 Kilogram Per Day

- 5 Days

- Yes

- Within a certain price range free samples are available

- Packing is available on sheets & rolls formats as per customer preference, packing goods packed by paper packing, taped, goni, cartoon, PVC rapper finally dispatched.

- All India

Product Description

Enter Buying Requirement Details

Other Products in 'Butter Paper ' category

|

G K ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry