No Water Absorvennt

Product Details:

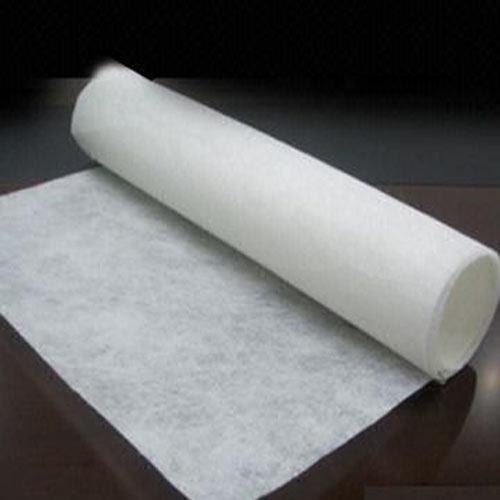

- Product Type No Water Absorvennt

- Color White

- Size Standard

- Usage Industrial

- Material Paper

- Click to View more

No Water Absorvennt Price And Quantity

- 149.0 INR/Kilograms

- 2000 Kilograms

No Water Absorvennt Product Specifications

- White

- Standard

- Industrial

- No Water Absorvennt

- Paper

No Water Absorvennt Trade Information

- Cash Against Delivery (CAD) Cash on Delivery (COD) Cash in Advance (CID) Cheque

- 2000 Kilograms Per Day

- 5 Days

- Free samples available with shipping and taxes paid by the buyer

- All India

Product Description

1. Definition: Non-water absorbent paper is a type of paper designed specifically not to absorb water or moisture. Unlike traditional papers that are porous and absorb liquids, this type is treated or manufactured in such a way that it resists water absorption. This characteristic is especially useful in applications where moisture resistance is essential.

2. Key Specifications:

-

Composition: Typically made from wood pulp, synthetic fibers, or a combination of both. It may also include water-resistant additives such as hydrophobic chemicals, coatings, or treatments.

-

Weight: Paper weight is often expressed in grams per square meter (gsm) or pounds per ream. Non-water absorbent papers can vary in weight depending on their intended use (e.g., lightweight for printing or heavier for protective applications).

-

Thickness: Can range from thin, flexible sheets to thick, rigid boards. Thickness is important depending on whether the paper is used for packaging or protective purposes.

-

Coating: The paper may have a special coating (like a polymer layer) that prevents water penetration. This can be a glossy, matte, or textured finish depending on the intended use.

-

Moisture Resistance: The ability to resist water penetration is a key specification. This is often tested through techniques such as the water droplet test, where the papers ability to repel or resist water is evaluated.

-

Tensile Strength: This measures the paper's strength when stretched, which is important for durability in handling without breaking down, especially in wet environments.

-

Opacity: Depending on the application (e.g., packaging or printing), opacity may be a concern. Non-absorbent papers may have low opacity due to the coatings applied to them.

-

Appearance: Non-water absorbent papers can come in various finishes, such as smooth, glossy, or textured. Color options range from natural whites to custom colors depending on the manufacturing process.

3. Uses and Applications:

-

Packaging: Used for packaging materials, especially where the paper needs to resist water damage, such as in food packaging, pharmaceutical packaging, and shipping materials.

-

Printing: Certain types of non-water absorbent paper are used in high-end printing or for applications where ink retention without smudging is essential.

-

Protective Covering: Used for protective wraps, especially in environments where moisture could cause damage to goods or documents.

-

Craft and Art Supplies: Often used for arts and crafts, where the surface needs to resist the effects of liquid mediums like paints or glues.

-

Outdoor Use: For materials that will be exposed to the elements, such as menus or maps that need to remain readable and intact despite potential exposure to moisture.

4. Advantages:

-

Water Resistance: The primary benefit is the ability to resist water and moisture, making it suitable for wet environments or moisture-sensitive products.

-

Durability: Can withstand handling without breaking down, even when exposed to humid or wet conditions.

-

Preservation of Print: In printing applications, non-absorbent paper helps preserve the clarity and quality of printed images, preventing smudging or fading.

5. Limitations:

-

Cost: The production of non-water absorbent paper may involve additional treatments, making it more expensive than regular paper.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Paper Rope' category

|

G K ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry