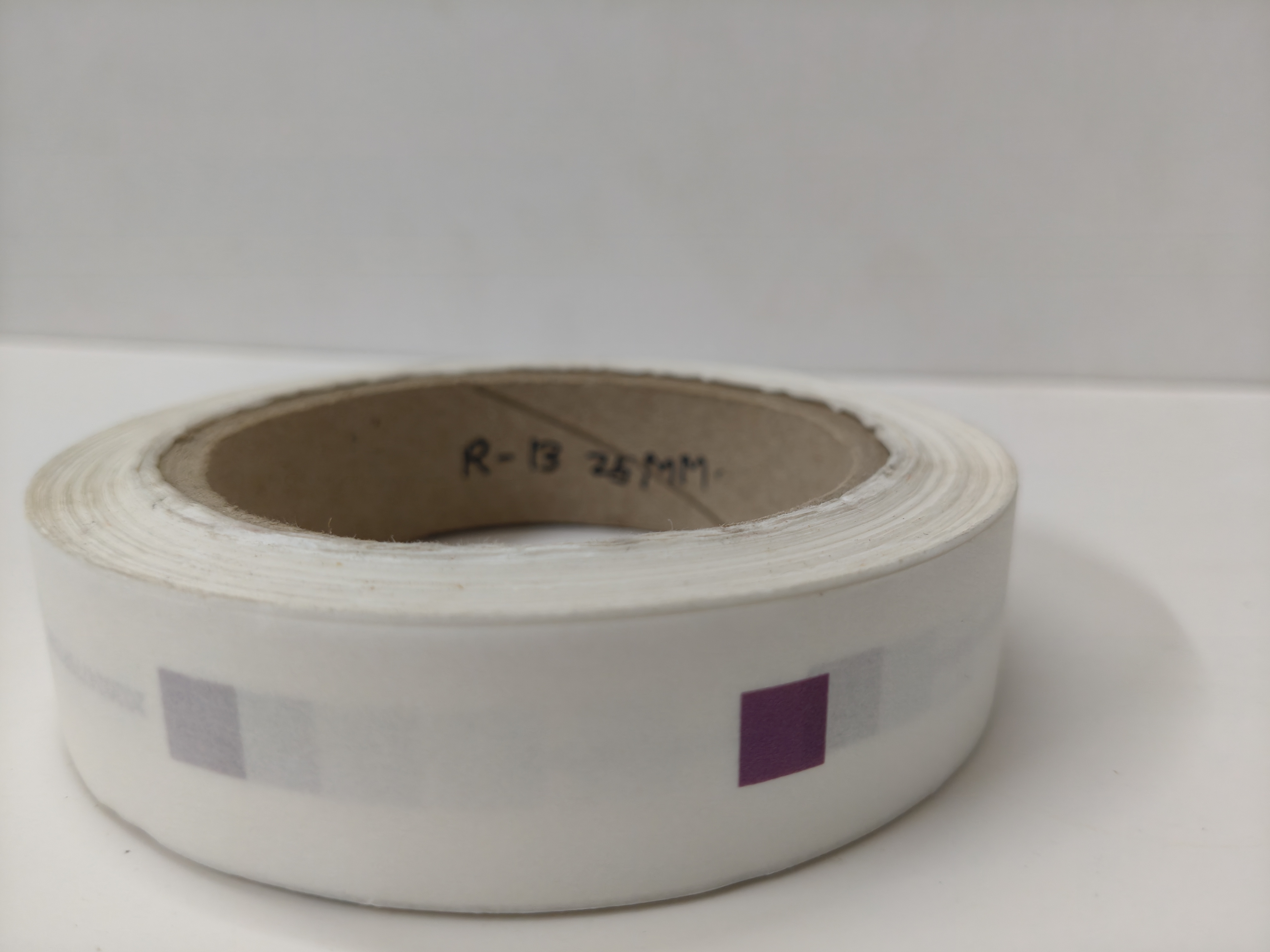

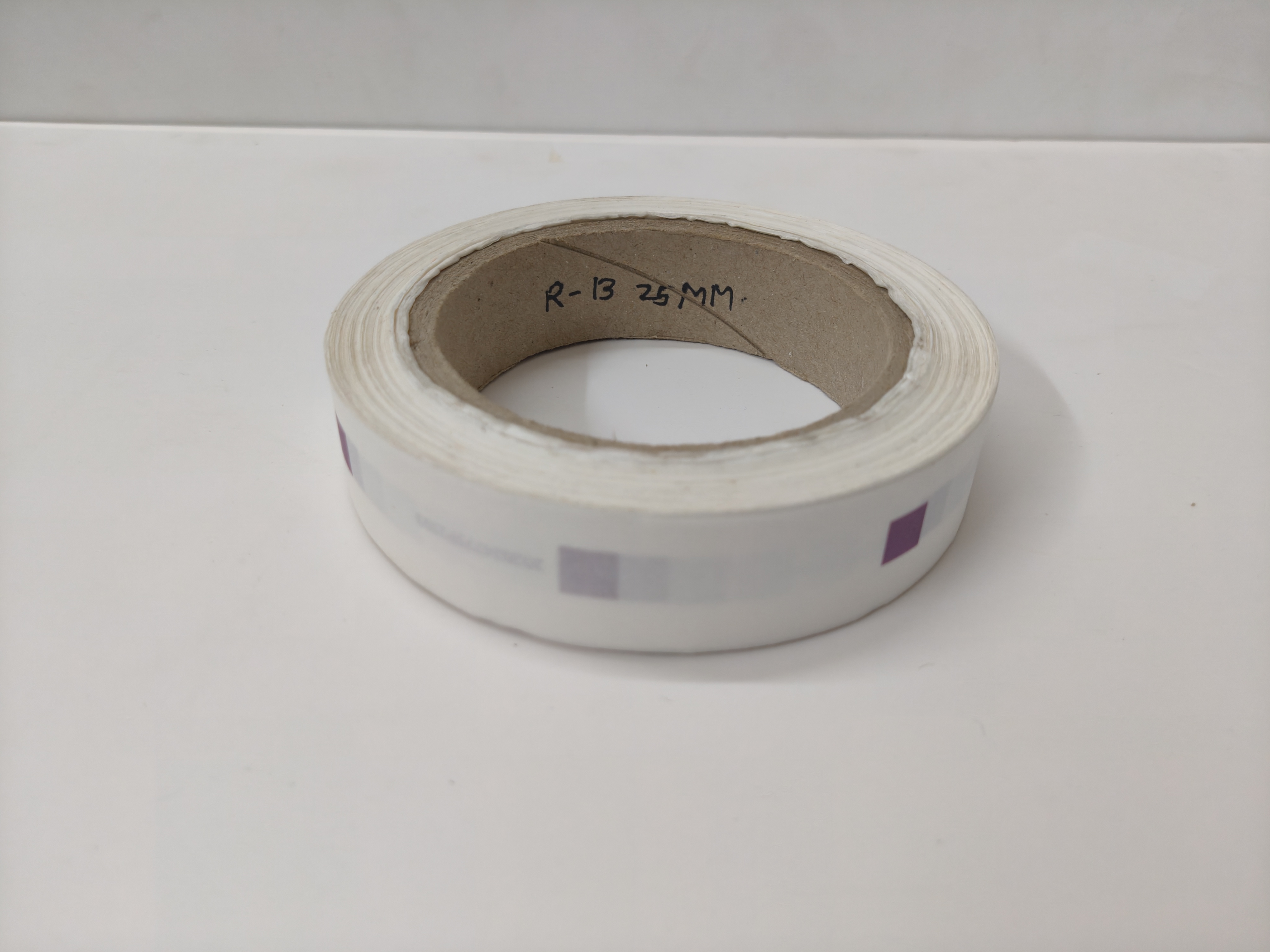

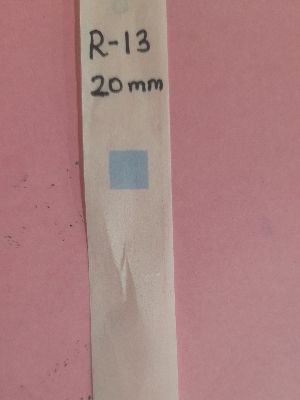

pad printed uncoated paper

Product Details:

pad printed uncoated paper Price And Quantity

- 200

- 98.0 INR

pad printed uncoated paper Trade Information

- Cash Against Delivery (CAD) Cash on Delivery (COD) Cash Advance (CA) Cash in Advance (CID)

- 2000 Per Day

- 5 Days

- Within a certain price range free samples are available

- Packing is available on sheets & rolls formats as per customer preference, packing goods packed by paper packing, taped, goni, cartoon, PVC rapper finally dispatched.

- All India

Product Description

Pad Printed Uncoated Paper refers to paper that has not been coated with any additional materials, combined with the process of pad printing, which is commonly used for applying logos, designs, and text to the paper. Pad printing is a direct printing technique that involves transferring an image from a silicone pad to a surface, which in this case, is uncoated paper. The result is a print that maintains the natural, tactile feel of the uncoated paper while providing a clear, precise image.

Key Features and Properties of Pad Printed Uncoated Paper:

-

Uncoated Paper Surface:

- Natural Texture: Uncoated paper retains its raw, natural texture, which gives it an organic, matte appearance. This texture contributes to a more earthy, rustic aesthetic, perfect for brands or products that emphasize eco-friendliness and authenticity.

- Absorption: Uncoated paper is absorbent, which affects how the ink from the pad printing process adheres to the paper. This can result in a more subdued and soft appearance of printed images, giving the print a natural, understated look.

- Matte Finish: Unlike glossy or coated papers, uncoated paper has a matte finish that doesn't reflect light. This finish provides a more subtle, soft effect for printed designs, ideal for minimalist or vintage branding.

-

Pad Printing Process:

- Precision: The pad printing process is highly precise and capable of transferring detailed images and text onto uncoated paper. The silicone pad picks up ink from the engraved printing plate and transfers it to the paper, ensuring a sharp, accurate reproduction of the design.

- Multi-Surface Printing: Pad printing is versatile and can be used not just on flat surfaces, but also on slightly curved or irregular surfaces. While uncoated paper is typically flat, this characteristic makes it useful for printing on a variety of packaging, labels, or other paper products.

- Ink Types: The inks used for pad printing on uncoated paper are typically solvent-based or UV-cured, depending on the desired effect and application. These inks are designed to dry quickly and adhere to uncoated paper effectively.

-

Advantages of Pad Printing on Uncoated Paper:

- Detail and Clarity: Pad printing can produce very fine details, allowing for the reproduction of logos, small text, and intricate patterns with great precision, even on the absorbent surface of uncoated paper.

- Durability: The print created through pad printing is durable and resistant to fading, especially if UV inks are used. This ensures that logos or designs on uncoated paper maintain their appearance over time, even with regular handling.

- Customizability: Pad printing offers great flexibility in terms of design, allowing businesses to create custom prints on uncoated paper that can be tailored to fit specific branding needs.

- Eco-Friendly: Using uncoated paper combined with pad printing allows for a more eco-friendly solution compared to heavily processed coated papers, especially if sustainable, recycled paper is used.

-

Design Considerations:

- Ink Absorption: Uncoated paper absorbs ink more than coated papers. While this creates a natural and soft finish, it can also cause the ink to appear slightly muted or faded. Designers should take this into account when choosing colors and line thicknesses for their logos or text.

- Print Colors: While pad printing works well with a wide range of colors, the absorbent nature of uncoated paper can cause printed colors to look more subdued. This works well with earth tones or muted shades, but vivid or neon colors may not appear as sharp or vibrant as they would on coated papers.

- Text and Logo Size: For best results, its recommended to use simple and bold designs with clear fonts. Fine lines or very small text might not reproduce well due to ink absorption and the texture of the uncoated paper.

-

Applications of Pad Printed Uncoated Paper:

- Packaging: Pad printed uncoated paper is widely used for product packaging, especially for eco-conscious or artisanal products. The matte finish of uncoated paper paired with a clean pad-printed logo gives packaging a sophisticated yet natural look.

- Business Cards: The tactile feel of uncoated paper makes it a popular choice for premium business cards. Pad printing can be used to apply logos, names, and other design elements with clarity and precision.

- Labels and Tags: For product labels or hang tags, pad printing on uncoated paper provides a high-quality print with a natural, rustic finish. This is particularly popular in industries like handmade goods, organic products, or luxury goods.

- Stationery: Letterheads, invitations, and brochures can also benefit from the natural and professional appearance of uncoated paper printed with pad printing.

- Marketing Materials: Brochures, flyers, and other promotional materials can feature pad-printed designs that stand out with the unique texture of uncoated paper. This approach is especially useful for businesses that emphasize sustainability or a premium, handcrafted image.

- Product Packaging: Custom printed boxes or bags made from uncoated paper can display a companys logo or product information in an elegant and durable way.

-

Benefits of Pad Printing on Uncoated Paper:

- Precision and Detail: The pad printing method allows for the reproduction of intricate designs with high precision, ideal for logos and fine text on uncoated paper.

- Custom Colors: Pad printing allows for a range of custom colors and even the use of special inks like metallics or pastels, depending on the design.

- Eco-Friendly: By using uncoated paper, which is often made from recycled materials, and combining it with pad printing (a less chemical-intensive process), this method provides a more sustainable option for custom printing needs.

- Cost-Effective for Small Runs: Pad printing is an efficient process for printing smaller quantities, which makes it a cost-effective solution for custom prints on small batches or limited edition packaging.

-

Considerations:

- Color Fading: Due to the absorbent nature of uncoated paper, the colors printed with pad printing may appear more muted than they would on coated papers. This is something to keep in mind when designing for high-impact visual designs.

- Durability of Print: While pad printing on uncoated paper is relatively durable, it may not be as resistant to abrasion as prints on coated papers. If the printed product is subject to rough handling, extra protection, like lamination, might be considered.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Silicon Coated Paper' category

|

G K ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry