Writing Rubber Paper

Product Details:

- Color White

- Size Standard

- Usage Industrial

- Product Type Writing Rubber Paper

- Material Paper

- Click to View more

Writing Rubber Paper Price And Quantity

- 171.0 INR/Kilograms

- 200 Kilograms

Writing Rubber Paper Product Specifications

- White

- Industrial

- Writing Rubber Paper

- Paper

- Standard

Writing Rubber Paper Trade Information

- Paypal Cash Against Delivery (CAD) Cash on Delivery (COD) Cash in Advance (CID) Cheque

- 2000 Kilograms Per Day

- 5 Days

- Sample costs shipping and taxes has to be paid by the buyer

Product Description

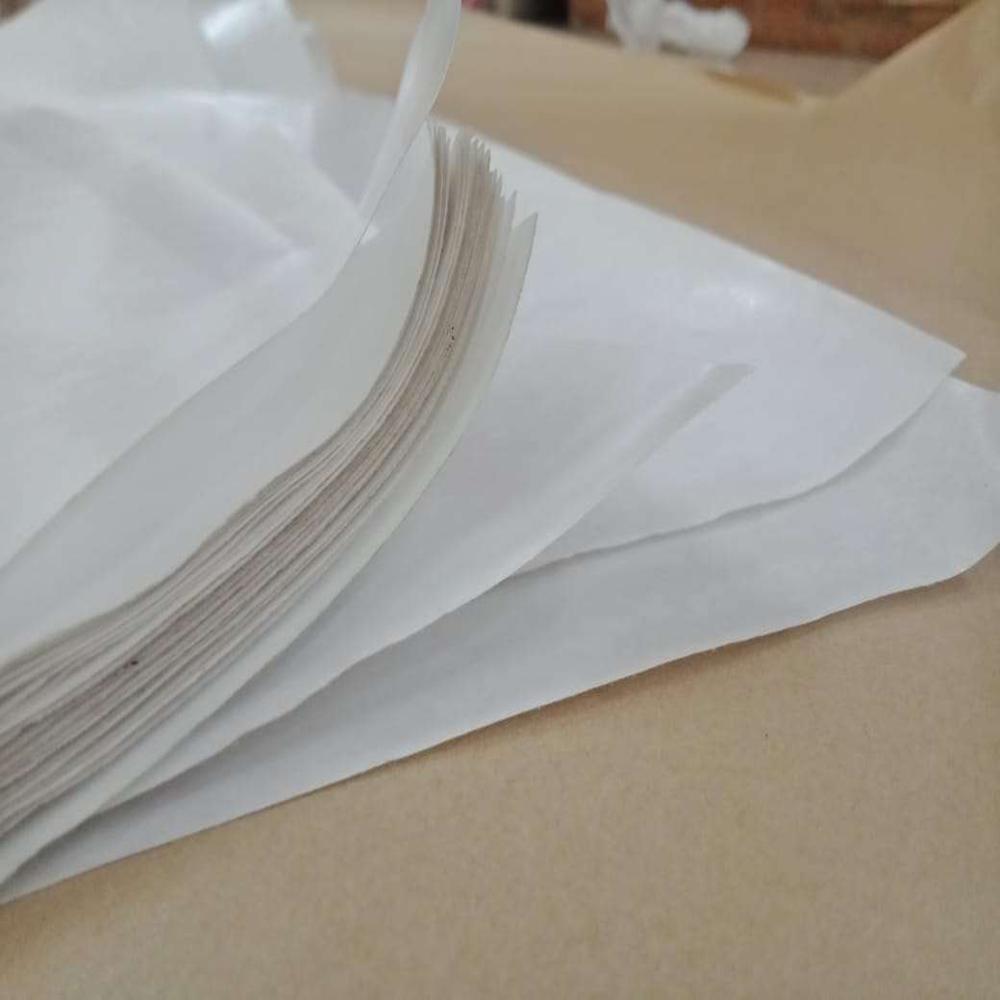

1. Introduction Rubber paper, also referred to as "rubberized paper" or "rubber-coated paper," is a specialized type of paper designed for applications requiring enhanced durability, flexibility, and resistance to moisture. It is commonly used in industries such as packaging, printing, and insulation, and serves as a protective layer for various products.

2. Material Composition Rubber paper typically consists of a combination of:

- Base Paper: High-quality, durable paper that serves as the foundation.

- Rubber Coating: A thin layer of rubber, either natural or synthetic, applied to one or both sides of the paper. The rubber may be vulcanized or thermally bonded to enhance its characteristics.

3. Key Features

- Moisture Resistance: The rubber coating provides an excellent barrier against water, making the paper suitable for outdoor or humid environments.

- Durability: The rubber coating adds strength, flexibility, and resistance to tearing and abrasion.

- Flexibility: The rubber layer increases the paper's flexibility, allowing it to bend or stretch without damage.

- Chemical Resistance: The rubber coating offers a degree of resistance to oils, acids, and other chemicals.

- Temperature Resistance: Rubber-coated paper can withstand a range of temperatures, providing thermal protection in various industrial settings.

- Recyclability: Depending on the rubber material used, rubber paper may be recyclable, making it an eco-friendly option.

4. Applications

- Packaging: Rubber paper is often used for protective packaging materials, such as wraps, pads, or liners, to protect sensitive products from moisture and damage.

- Insulation: In industrial applications, it can act as an insulation material, especially in electrical and mechanical systems.

- Gaskets and Seals: The paper can be used to make gaskets or seals due to its compressibility and durability.

- Printing: In some cases, rubber paper is used for printing applications, especially where moisture resistance is required.

- Agriculture: Used in applications like seed packaging, where moisture protection is crucial for maintaining seed quality.

5. Performance Characteristics

- Tensile Strength: The ability to resist breaking or tearing under stress.

- Elongation at Break: The degree to which the paper can stretch before breaking.

- Rubber Adhesion: The quality of the bond between the rubber layer and the base paper, which influences the overall durability and performance.

- Surface Texture: Depending on the application, the surface may be smooth, rough, or embossed.

6. Manufacturing Process The production of rubber paper generally involves the following steps:

- Base Paper Preparation: Selecting and processing the base paper material.

- Rubber Mixing: Preparing the rubber compound by mixing natural or synthetic rubber with additives to achieve the desired properties.

- Coating: Applying the rubber compound to the surface of the paper using techniques like dipping, spraying, or roller coating.

- Curing: Curing or vulcanizing the rubber to ensure it adheres firmly to the paper and develops the desired characteristics.

- Cutting and Finishing: Cutting the finished rubber paper into desired sizes and performing any additional finishing steps, such as embossing or printing.

7. Specifications

- Thickness of Paper: Typically ranges from 50 to 250 microns, depending on the desired strength and flexibility.

- Rubber Coating Thickness: The rubber layer thickness can vary between 20 to 100 microns.

- Tensile Strength: Minimum of 50 MPa (Megapascals), depending on the grade of paper.

- Moisture Resistance: Should withstand up to 90% humidity without significant degradation.

- Temperature Range: Can tolerate temperatures from -20C to +120C (depending on rubber type).

- Shelf Life: Typically up to 2 years if stored under recommended conditions.

8. Storage and Handling Rubber paper should be stored in a cool, dry place away from direct sunlight and extreme temperatures. It should be kept in a flat, moisture-free environment to prevent warping or adhesion of layers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Paper Rope' category

|

G K ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry