G1 Duplicate |

Logo Printed coated side paper

(GSM: 60 & CODE: R28) Silicone coated release paper imparts certain qualities to the paper including weight release, surface gloss, smoothness and reduced absorbency. The silicone coated release paper can then be used in food packaging

HAVANA YELLOW COATED 1SIDE PAPER

GSM:90 & CODE: R33) Silicone coated release paper imparts certain qualities to the paper including weight release, surface gloss, smoothness and reduced absorbency. The silicone coated release paper can then be used in food packaging, release paper and in magazines.

WHITE SILICON RELEASE PAPER 90 GSM

White Silicon One-Side Coated Paper 90 GSM is a type of paper that features a smooth, high-quality coating on one side, with the addition of a silicon coating on the non-coated side. This paper is primarily used in applications where a high degree of printability is required on the coated side and the uncoated side must have non-stick or release properties,

silicon paper brown uncoated

brown hawan paper one side coted Rs-150 pr kg GSM-90 Code-R32 Brown Hawan Paper is commonly used in Hindu religious rituals, especially for ceremonies like Hawan (a fire ritual or yajna). The paper is typically made from natural materials, often featuring a brown, unbleached appearance, which is associated with purity and simplicity in traditional practices. In the context of the Hawan ceremony, the paper is used to make offerings into the sacred fire. The offerings may include herbs, ghee (clarified butter), grains, and other ritual items. The paper is used to wrap or hold these offerings, ensuring they are properly placed into the fire during t

WHITE SILICON 2 SIDE COATED SILICON PAPER

ilicon-based coating (often called "Glossy" or "Matte" depending on the finish). Coating on Both Sides: The paper has a coating on both sides, ensuring a consistent finish for printing or other applications.1. Basis Weight: Weight: 60 GSM (Grams per Square Meter) The weight indicates that it is a relatively light paper, making it suitable for high-quality printing without being overly thick or rigid. 2. Coating: Type of Coating: S

WHITE SILICON ONE SIDE COATED PAPER 40 GSM

GSM: 40 & CODE: R1 Silicone coated release paper imparts certain qualities to the paper including weight release, surface gloss, smoothness and reduced absorbency.. The silicone coated release paper can then be used in food packaging, release paper and in magazines.

Designed Printed Silicon 1 Side Coated Paper Rolls

Available on Rolls, Sheets, Reams & Strips - Patti Etc. Designed Printed Silicon 1-Side Coated Paper refers to paper that has been coated with a layer of silicone on one side, making it heat-resistant, non-stick, and water-resistant. The other side of the paper can be printed with designs, logos, patterns, or text. This combination of features makes it a versatile material used across a wide range of industries.

"Veg Green/Non-Veg Red Printed One-Side Coated Food-Grade Butter Paper, Greaseproof & Moisture-Resistant for Food Packaging & Wrapping"

Veg Green/Non-Veg Red Printed Food-Grade Butter Paper is ideal for wrapping, packaging, and storing food, lining baking pans, and distinguishing vegetarian and non-vegetarian items in takeout or catering.

LOGO CONTINUE PRINTED UNCOATED PAPER CYL 6000

GSM: 40 & CODE: R3) Silicone coated release paper imparts certain qualities to the paper including weight release, surface gloss, smoothness and reduced absorbency.

Special Food Grade 1 Side Coated Paper

GSM: 60 & CODE: R27, Silicone coated release paper imparts certain qualities to the paper including weight release, surface gloss, smoothness and reduced absorbency. The silicone coated release paper can then be used in food packaging, release paper and in magazines. However the coating formulation needs careful consideration for the chemical additives and dispersants being used. The coating can be carried out by adjusting the thickness of coating, speed of coating and the curing temperature. Silicone coated release paper coating comprises two-component and three-component systems for pressure sensitive tapes and labels. Silicone coated release paper a range of silicones designed to be applied on one or both sides of a paper or film substrate. Also known as silicone coated release liners, they are used to protect sticky surfaces and to ease their handling. Silicone coated release paper are used in a wide array of markets and applications where it is critical to achieve a perfect coating to protect and deliver materials such as pressure sensitive adhesives (PSA) used in tapes and labels to their end destination. Beyond protection of self-adhesive or sticky materials they are also fantastic process aids and are used to enable casting and composite production processes and offer non-stick hygienic solutions for cooking and baking. Silicone coated release liner paper has three different type of coating such as: Tin Coating, Platinum Coating and Glassine or Silicone Coating. We can provide Silicone coated release liner paper in custom size such roll and sheet form. The standard size for Silicone coated release liner paper is 20x30inch in sheet form and 20inch width in roll form. Our minimum order quantity for Silicone coated release liner paper is 200kg. Silicone coated release liner paper we have start from 40 to 120gsm...3. Finish: Natural Texture: Since the paper is uncoated, it retains the natural texture of the pulp. This can range from a slightly rough, rustic texture to a smoother, more refined feel. The uncoated surface is ideal for designs that benefit from a more organic or natural look. Matte Appearance: Uncoated papers typically have a matte finish, meaning they don™t have the glossy or shiny appearance found in coated papers. This results in a more subtle, understated aesthetic. 4. Print Quality: Ink Absorption: Uncoated paper absorbs ink more than coated paper, which can lead to slightly softer edges and a more muted color profile. However, this gives prints a more natural look, which is often desirable in artistic or eco-conscious applications.

Name Printed Roll & Sheets Silicon Coated One Side 120 gsm

GSM: 40 to 120 CODE: R42 Silicone coated release paper imparts certain qualities to the paper including weight release, surface gloss, smoothness and reduced absorbency. The silicone coated release paper can then be used in food packaging, release paper and in magazines. However the coating formulation needs careful consideration for the chemical additives and dispersants being used. The coating can be carried out by adjusting the thickness of coating, speed of coating and the curing temperature. Silicone coated release paper coating comprises two-component and three-component systems for pressure sensitive tapes and labels.

YELLOW COATED ONE SIDE SILICONE Paper

GSM: 60 & CODE: R21 Silicone coated release paper imparts certain qualities to the paper including weight release, surface gloss, smoothness and reduced absorbency. The silicone coated release paper can then be used in food packaging, release paper and in magazines.. However the coating formulation needs careful consideration for the chemical additives and dispersants being used. The coating can be carried out by adjusting the thickness of coating, speed of coating and the curing temperature. Silicone coated release paper coating comprises two-component and three-component systems for pressure sensitive tapes and labels. Silicone coated release paper a range of silicones designed to be applied on one or both sides of a paper or film substrate. Also known as silicone coated release liners, they are used to protect sticky surfaces and to ease their handling. Silicone coated release paper are used in a wide array of markets and applications where it is critical to achieve a perfect coatin

Name Alphabet Printed Silicon 1 Side Coated Roll

40 GSM, Available on Rolls, Reams, Patti - Strips, Sheets Etc. A Printed Silicon 1-Side Coated Roll is a type of paper that combines a silicone coating on one side, typically used for its non-stick, moisture-resistant, and heat-resistant properties. The printed aspect means that the paper can be custom printed with logos, designs, or other patterns for branding or aesthetic purposes. Characteristics: Silicon Coating: The paper has a silicone coating on one side, which imparts properties like heat resistance (typically between 150C to 250C), non-stick surfaces, and water resistance. Printed Design: The roll of paper is often printed with logos, branding, or decorative patterns, making it suitable for custom packaging or promotional purposes, such as food packaging or baking sheets. Applications: These rolls are commonly used in industries like: Food industry: For baking, roasting, or cooking, where food should not stick to the surface. Packaging: For use in branded packaging materials like gift wrapping, baking sheets, or disposable liners. Industrial uses: In applications where a non-stick, heat-resistant surface is needed. Typical Uses: Baking Sheets: Often printed with branding or decorative elements, commonly used in the food service industry. Packaging: Printed silicon-coated rolls can be used in food and product packaging that requires a heat-resistant and non-stick surface. Industrial Applications: Used in applications that require both heat resistance and a smooth, printable surface for branding or identification purposes. If you are looking for a specific supplier or manufacturer, many paper product suppliers offer custom printing services on silicon-coated rolls. You can contact them for specific details on materials, heat tolerance, and printing options..

Logo Continue Printed Coated One Side paper

The Logo Continue Printed Coated One-Side Paper is specially designed to elevate the quality of your printed products. Featuring a coated surface on one side, it ensures crisp, vibrant colors and sharp details for your logo and branding. The coating enhances print durability, making it ideal for high-quality promotional materials.

BROWN COATED SILICON PAPER ROLL 120GSM

(GSM: 40 & CODE: B9) Mg kraft white paper, Mg Kraft Paper Sheet, machine glazed Kraft paper 500mm are used for food packaging available in roll form and sheet form as per your order kraft paper. we can provide custom size we have start from 40 to 120gsm.

MG Kraft White Uncoated Paper

(GSM: 40 & CODE: B9) Mg kraft white paper, Mg Kraft Paper Sheet, machine glazed Kraft paper 500mm are used for food packaging available in roll form and sheet form as per your order kraft paper. we can provide custom size we have start from 40 to 120gsm.

UNCOATED PAPER ROLL & SHEET (ABOVE 20 INCH 5RS EXTRA) PACKING CUTTING

Uncoated Paper Roll & Sheets 60 GSM refers to a type of paper that does not have any coating on its surface, providing a natural, unpolished finish. This paper is typically used for applications where printability is essential, but a more nat

Coated 1 Side 2mm side uncoated Paper Roll

GSM-40 CODE-R5, 480 Sheets 20X30 @ 998 Cutting Charge Extra. Silicon Uncoated Paper (also known as Silicone Paper or Silicone Release Paper) is a type of paper that is treated with silicone to provide non-stick, moisture-resistant, and heat-resistant properties. Unlike coated paper, which typically has a smooth, glossy finish, uncoated silicone paper retains a natural texture while benefiting from the non-stick and protective qualities of silicone. Key Features of Silicon Uncoated Paper: Silicone Coating: The primary feature of silicone uncoated paper is that it is treated with silicone, but it remains uncoated, meaning it doesn™t have a glossy or heavy finish. This treatment provides the paper with non-stick properties, making it ideal for various applications, particularly in baking and food packaging. The silicone layer creates a release surface, allowing it to withstand high temperatures without sticking to food items or baking goods. Non-Stick Surface: The silicone treatment gives

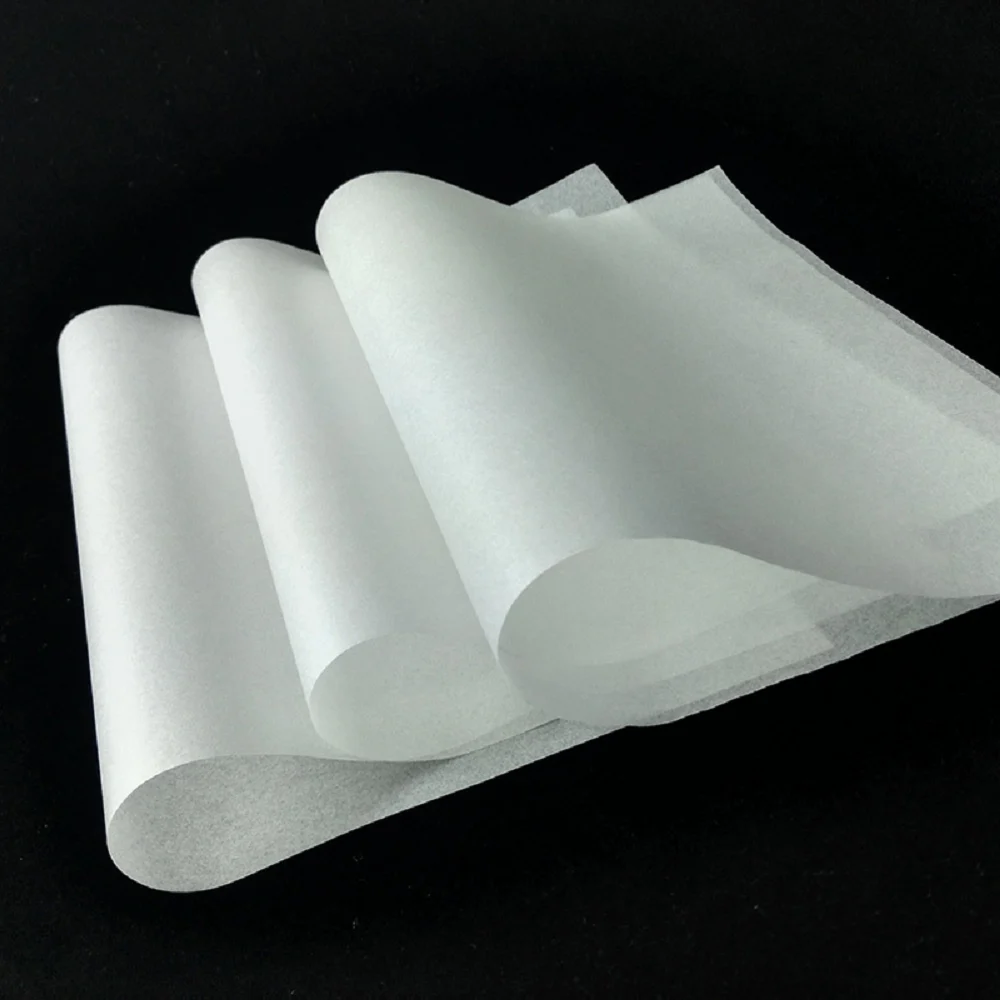

White Uncoated Paper Roll And Sheets

GSM-40 CODE-R5, 480 Sheets 20X30 @ 998 Cutting Charge Extra. Silicon Uncoated Paper (also known as Silicone Paper or Silicone Release Paper) is a type of paper that is treated with silicone to provide non-stick, moisture-resistant, and heat-resistant properties. Unlike coated paper, which typically has a smooth, glossy finish, uncoated silicone paper retains a natural texture while benefiting from the non-stick and protective qualities of silicone. Key Features of Silicon Uncoated Paper: Silicone Coating: The primary feature of silicone uncoated paper is that it is treated with silicone, but it remains uncoated, meaning it doesn™t have a glossy or heavy finish. This treatment provides the paper with non-stick properties, making it ideal for various applications, particularly in baking and food packaging. The silicone layer creates a release surface, allowing it to withstand high temperatures without sticking to food items or baking goods. Non-Stick Surface: The silicone treatment gives

HAWANA GOLDEN DOUBLE SIDE COATED PAPER

GSM: 90 CODE: R36 HAWANA GOLDEN COATED 2 SIDE paper imparts certain qualities to the paper including weight release, surface gloss, smoothness and reduced absorbency.

UNCOATED PAPER ROLL & SHEETS 90GSM

Uncoated paper with a weight of 60 GSM (grams per square meter) refers to a type of paper that is not coated with a glossy or matte finish, making it more natural and absorbent. It is commonly used for a variety of purposes, including printing, stationery, and packaging.

Printed Brown Hawana 1 Side Coated Paper

Brown Packing Paper 60 GSM is a type of kraft paper commonly used for packaging, wrapping, and protecting products. It is often chosen for its strength, durability, and eco-friendly nature. The 60 GSM (grams per square meter) refers to the thickness and weight of the paper, indicating that it is relatively sturdy compared to lighter paper options.

WHITE SILICON TWO SIDE COATED PAPER 90 GSM

90 GSM (Grams per Square Meter): This weight is considered moderate, providing a balance between durability and flexibility. The 90 GSM weight is ideal for various applications, ensuring the paper is light enough for easy handling while still robust for quality printing and performance. Two-Side Coated Paper: The paper is coated on both sides, giving it a smooth, glossy, or matte finish on each side. This coating ensures high-quality print performance and a consistent look across both sides.

WHITE SILICON ONE SIDE COATED PAPER 120 GSM

White Silicon One Side Coated Paper (120 GSM) is a type of paper that features a glossy, smooth coating on one side, while the other side remains uncoated or matte. This type of paper is commonly used in high-quality printing applications due to its ability to produce sharp, vibrant colors and crisp details. Here™s a breakdown of the

UNCOATED SILICON BASE PAPER BCW/MGK/SCK/CCK ROLL

The specification for Uncoated BCW/MGK/SCK/CCK Roll and Sheets (40 GSM) typically refers to a variety of paper or board products used in different industries like packaging, printing, or manufacturing. Below is a general outline of specifications that might be applicable for uncoated paper types such as BCW, MGK, SCK, or CCK at a grammage of 40 GSM (grams per square meter).

SPECIAL FOOD GRADE ONE SIDE COATED PAPER 40 GSM

Special Food Grade One-Side Coated Paper (40 GSM) is a type of paper that has been specifically designed and treated to meet food safety standards. This paper has been coated on only one side, offering a smooth, glossy finish ideal for use in food-related packaging and applications. Key Features:

WHITE SILICON TWO SIDE COATED PAPER 120 GSM

White Silicon Two-Side Coated Paper (120 GSM) refers to a type of paper that is coated with a layer of silicon or a silicone-based compound on both sides. This paper typically has a smooth, glossy finish due to the coating, which makes it suitable for high-quality printing, especially when vibrant colors or detailed images are needed. The 120 GSM (grams per square meter) measurement indicates the weight of the paper, and this weight makes it medium-thickness paper, often used in applications

|

|

|

G K ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry