Special Food Grade 1 Side Coated Paper

Product Details:

- Size NA

- Thickness NA

- Weight NA

- Width NA

- Moisture NA

- Bursting NA

- Color NA

- Click to View more

Special Food Grade 1 Side Coated Paper Price And Quantity

- 179 INR/Kilograms

- 200 Kilograms

- 12.00 - 12.00 INR/Kilograms

Special Food Grade 1 Side Coated Paper Product Specifications

- NA

- NA

- NA

- NA

- NA

- NA

- NA

- NA

- NA

- NA

- NA

- Printing

- Food Wrapping Paper Gift Wrapping Paper

- NA

- NA

Special Food Grade 1 Side Coated Paper Trade Information

- Mumbai

- Cash Against Delivery (CAD) Cash on Delivery (COD) Cash Advance (CA)

- 2000 Kilograms Per Day

- 5 Days

- Na

- Asia

- All India

- NA

Product Description

-

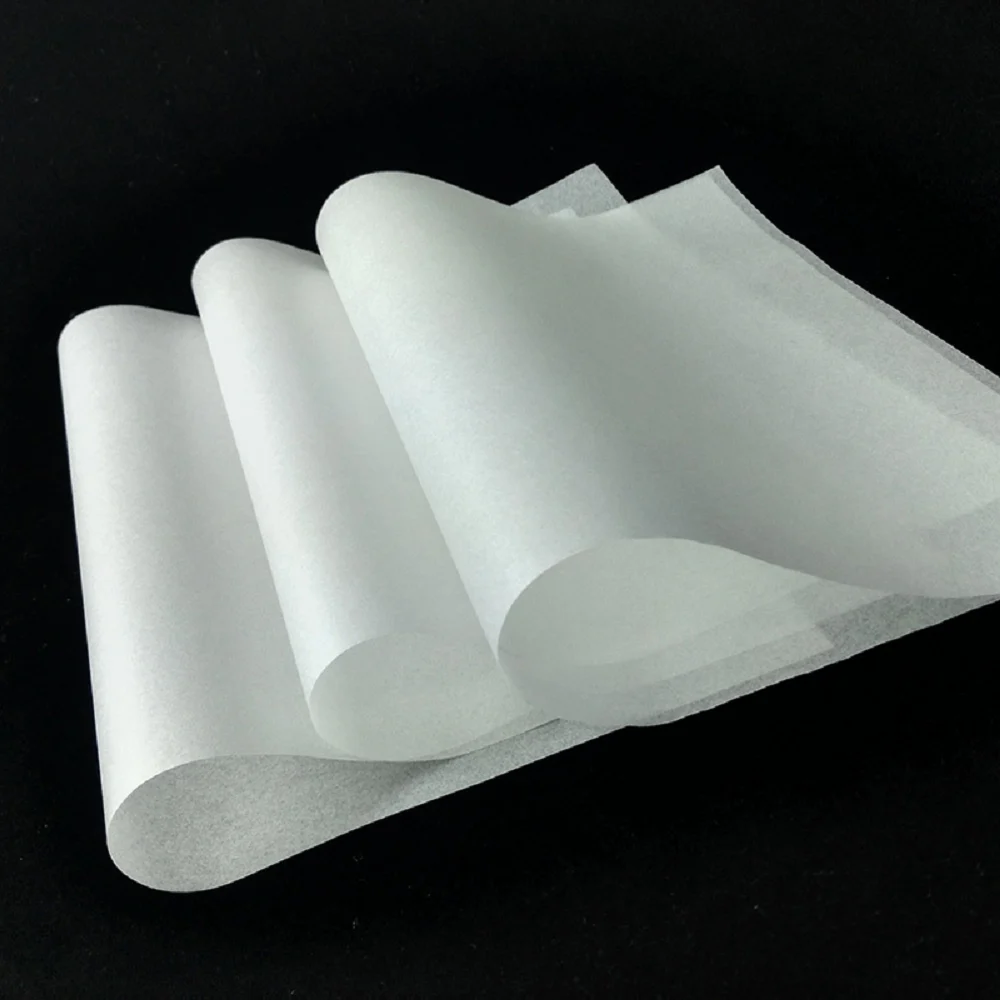

Natural Texture: Since the paper is uncoated, it retains the natural texture of the pulp. This can range from a slightly rough, rustic texture to a smoother, more refined feel. The uncoated surface is ideal for designs that benefit from a more organic or natural look.

-

Matte Appearance: Uncoated papers typically have a matte finish, meaning they don™t have the glossy or shiny appearance found in coated papers. This results in a more subtle, understated aesthetic.

-

Ink Absorption: Uncoated paper absorbs ink more than coated paper, which can lead to slightly softer edges and a more muted color profile. However, this gives prints a more natural look, which is often desirable in artistic or eco-conscious applications.

-

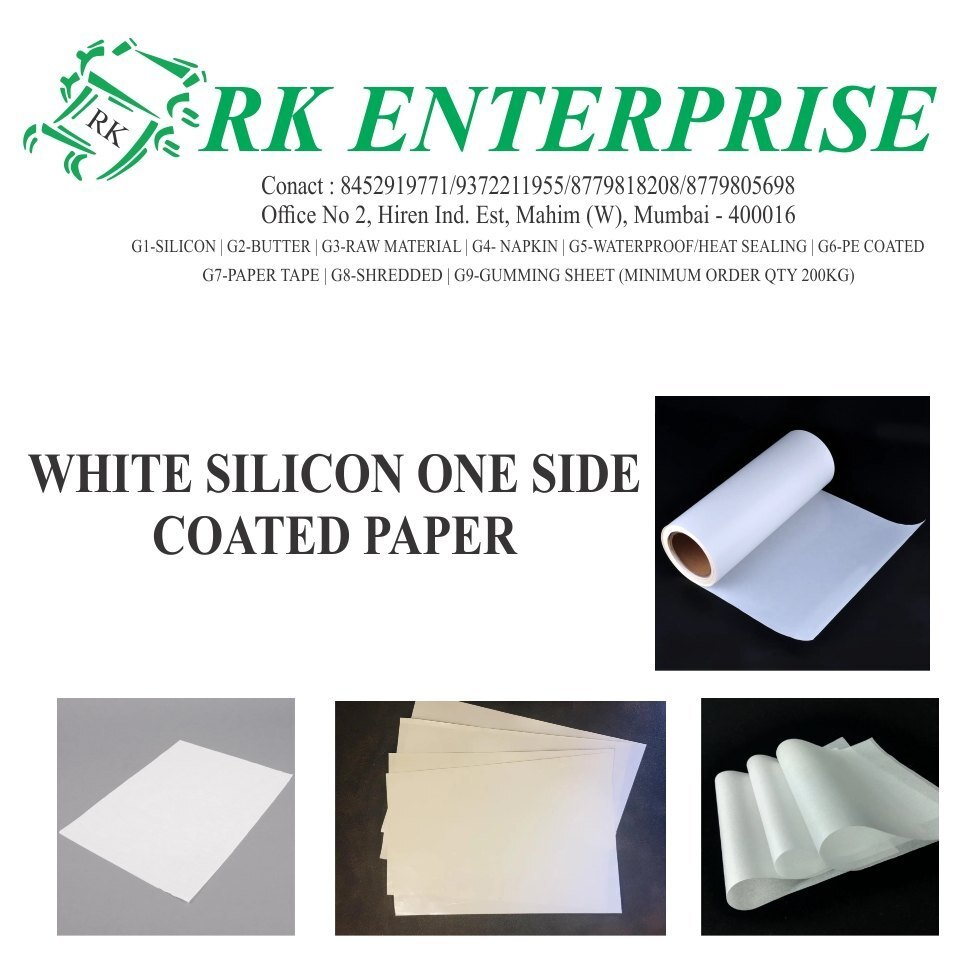

GSM: 60 & CODE: R27, Silicone coated release paper imparts certain qualities to the paper including weight release, surface gloss, smoothness and reduced absorbency. The silicone coated release paper can then be used in food packaging, release paper and in magazines. However the coating formulation needs careful consideration for the chemical additives and dispersants being used. The coating can be carried out by adjusting the thickness of coating, speed of coating and the curing temperature. Silicone coated release paper coating comprises two-component and three-component systems for pressure sensitive tapes and labels.

Silicone coated release paper a range of silicones designed to be applied on one or both sides of a paper or film substrate. Also known as silicone coated release liners, they are used to protect sticky surfaces and to ease their handling. Silicone coated release paper are used in a wide array of markets and applications where it is critical to achieve a perfect coating to protect and deliver materials such as pressure sensitive adhesives (PSA) used in tapes and labels to their end destination. Beyond protection of self-adhesive or sticky materials they are also fantastic process aids and are used to enable casting and composite production processes and offer non-stick hygienic solutions for cooking and baking.

Silicone coated release liner paper has three different type of coating such as: Tin Coating, Platinum Coating and Glassine or Silicone Coating. We can provide Silicone coated release liner paper in custom size such roll and sheet form. The standard size for Silicone coated release liner paper is 20x30inch in sheet form and 20inch width in roll form. Our minimum order quantity for Silicone coated release liner paper is 200kg. Silicone coated release liner paper we have start from 40 to 120gsm...3. Finish:

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'G1 Duplicate' category

|

G K ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry