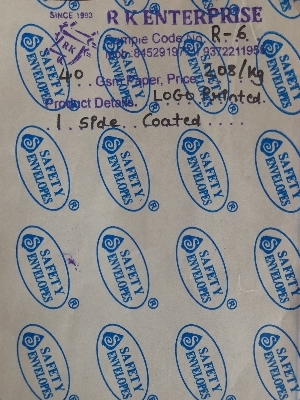

Call : 07971191787

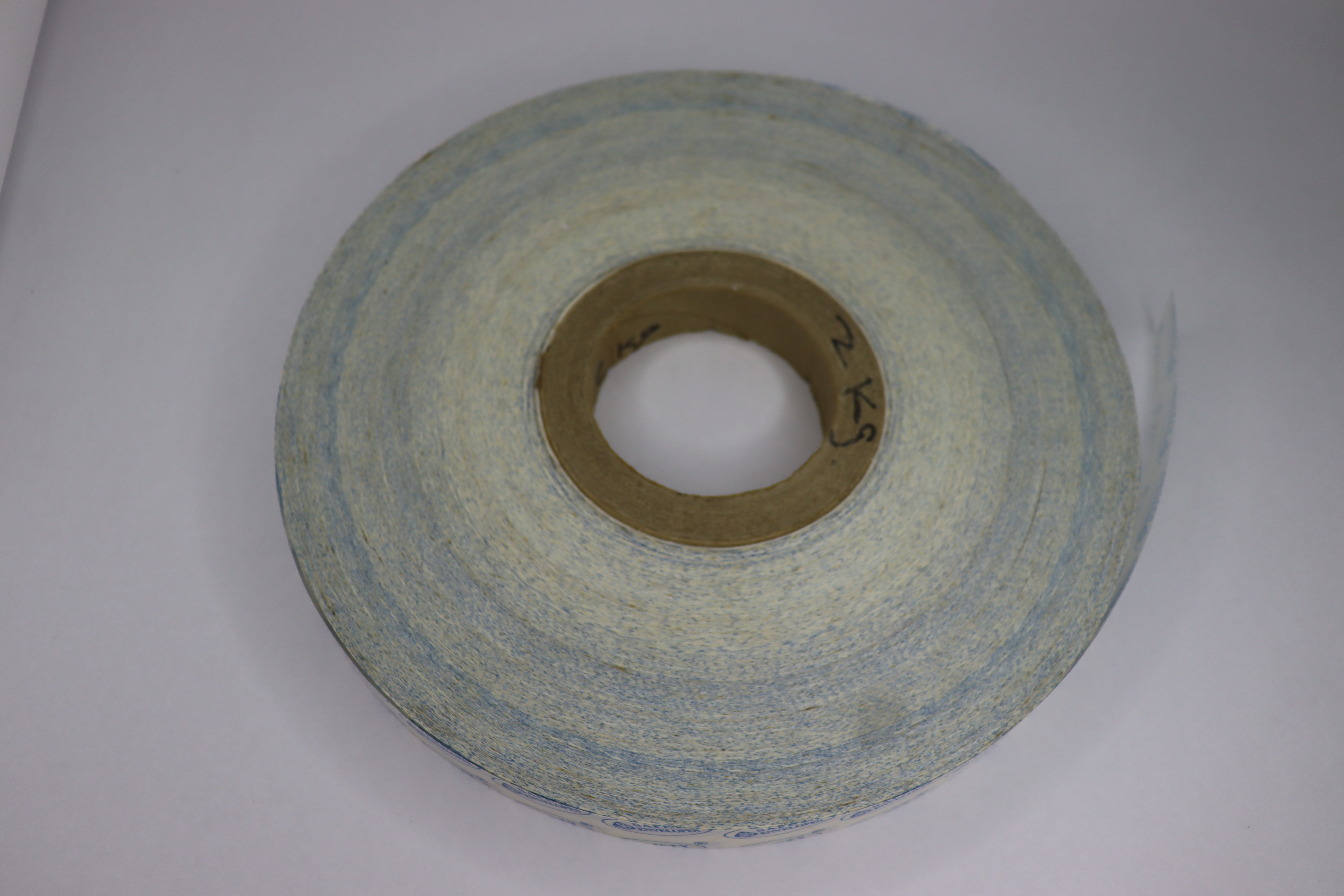

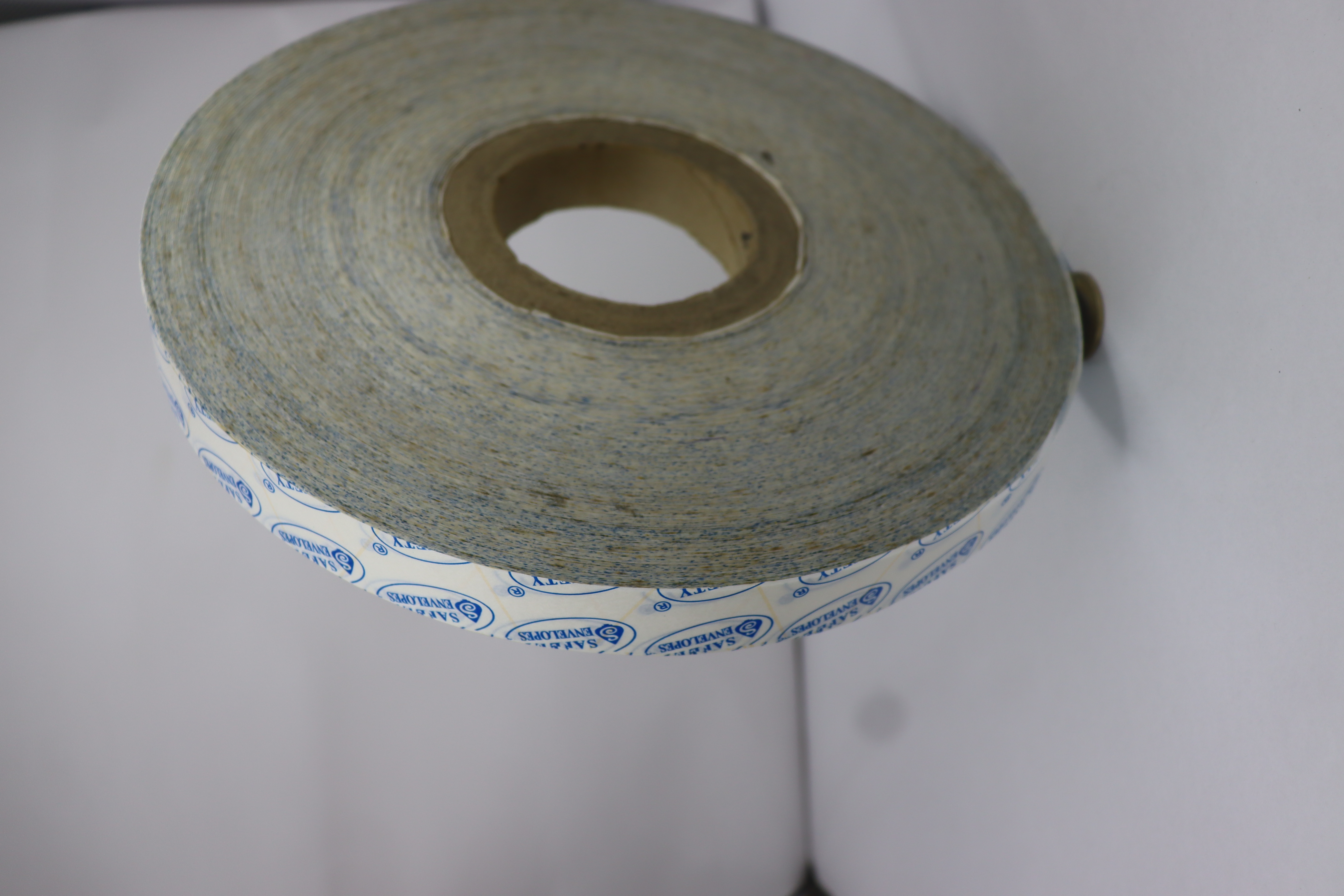

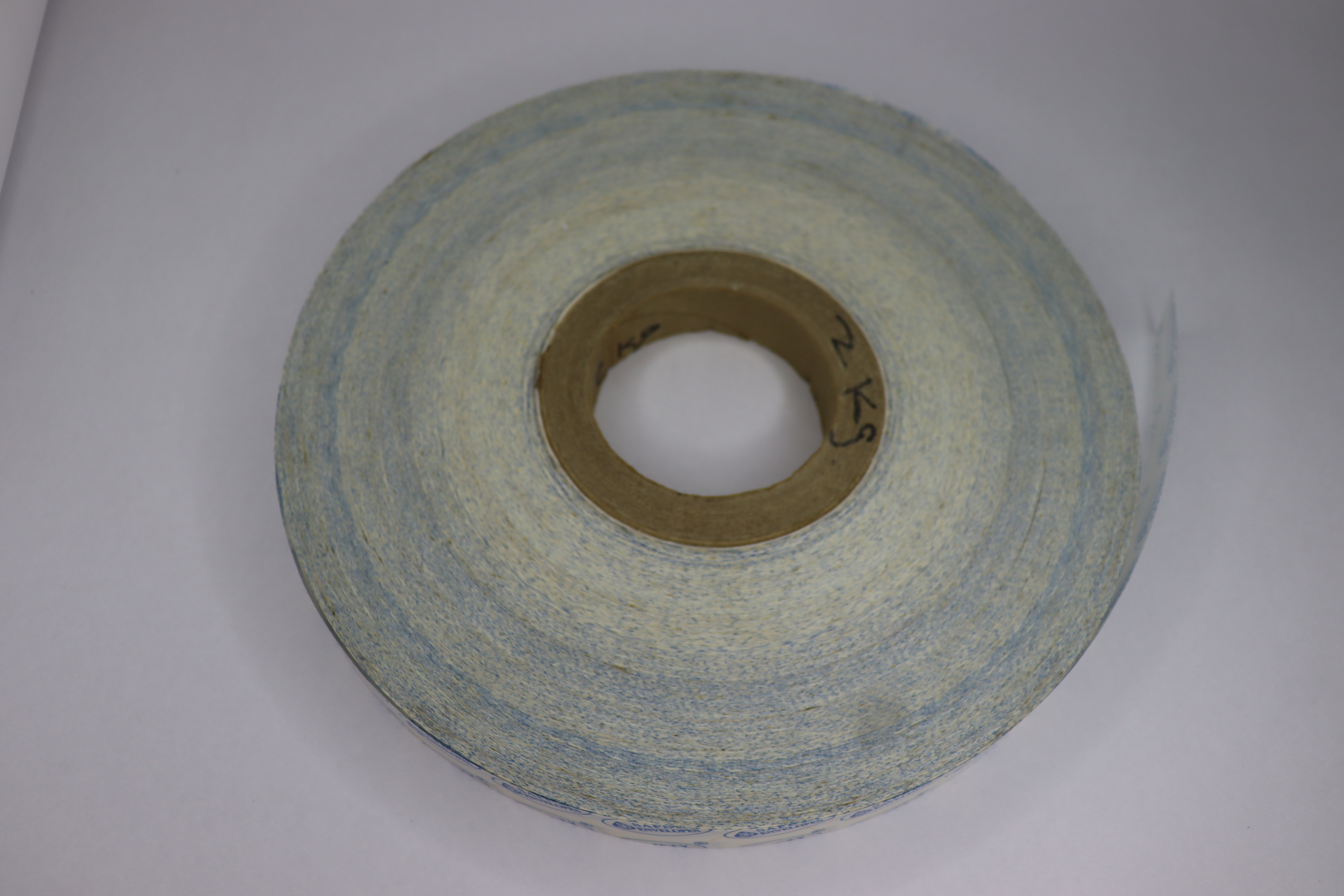

logo continue printed one side coated

208.0 INR

தயாரிப்பு விவரங்கள்:

X

விலை மற்றும் அளவு

- 200

வர்த்தகத் தகவல்கள்

- நாளொன்றுக்கு

- நாட்கள்

- No

- Packing is available on sheets & rolls formats as per customer preference, packing goods packed by paper packing, taped, goni, cartoon, PVC rapper finally dispatched.

தயாரிப்பு விளக்கம்

Creating a logo design for continuously printed one-side coated paper involves several steps to ensure the final product is both visually appealing and functional. When designing for a paper roll that is coated on one side, the design is printed on the uncoated (printable) side, while the coated side provides a protective layer, making the paper resistant to water, oils, and smudging.

Heres a comprehensive approach to designing a logo on continuously printed one-side coated paper:

1. Understanding the Paper and Coating:

- Coated Side (Non-Printable Side): This side of the paper is smooth, glossy, and water- and oil-resistant. It is not intended for printing but provides durability and protection for the printed design on the opposite side.

- Uncoated Side (Printable Side): The side to which your logo and design will be printed. The texture of the uncoated side allows better ink absorption, which affects the vibrancy and sharpness of your design. The finish here will be more matte compared to the coated side.

2. Design Considerations:

- Logo Placement: Since the paper is in a continuous roll, think of the design in terms of repetition. Ensure that the logo is placed consistently throughout the print to maintain brand continuity. The design may be applied as a repeating pattern, or the logo can be spaced periodically, depending on the purpose of the print.

- Resolution: Ensure that the logo is created in a high-resolution format (300 DPI or higher) to ensure clarity when printed. Since the paper is uncoated, the design might appear a little softer compared to a glossy surface, but it will still look crisp with the right resolution.

- Bleed Area: For continuous printing, you should ensure that theres a bleed (extra space around the design) to avoid any cutting issues when trimming the paper. A typical bleed area is about 3-5mm.

3. Color Palette and Ink:

- Color Choice: The uncoated surface can affect how certain colors appear. Lighter tones might look a little muted, while bold, rich colors (like dark blues, blacks, and reds) can pop well. Choose colors that complement the matte finish of the uncoated paper.

- Ink Type: Use inks compatible with the uncoated paper. Most commonly, water-based inks, solvent-based inks, or UV inks are used for printing on coated paper. These inks provide vibrant colors and ensure quick drying.

- Contrast: Ensure good contrast between the logo and the background. Since the coated side may have a glossy appearance, you want the logo to be legible and prominent on the matte, uncoated surface.

4. Logo Style:

- Simple and Bold: Logos designed for continuous printing on paper often work best when they are bold and clear. Overly complex logos with small intricate details may become blurred due to the ink absorption properties of the uncoated paper.

- Typography: If your logo includes text, select a typeface that is clear and legible even when printed on a matte surface. Sans-serif fonts often work well, as they are more readable in various sizes.

- Shapes and Icons: Logos that incorporate simple, geometric shapes or icons tend to print well on continuous rolls, ensuring that every part of the design is consistent and easy to repeat across the entire roll.

5. Layout for Continuous Printing:

- Repetition: Decide whether your logo will appear in a repeating pattern across the paper roll or if it will be printed in intervals. For packaging or wrapping, a repeating pattern (e.g., a logo spaced out evenly) can help maintain brand recognition over long lengths.

- Orientation: Ensure the orientation of the logo fits the rolls layout. For long strips of packaging or wrapping, the logo may be printed horizontally or vertically, depending on how the paper is used.

6. Technical Printing Considerations:

- Printing Method: The most common methods for printing on one-side coated paper rolls include flexographic printing (commonly used for packaging), rotogravure, or offset printing (for high-volume, high-quality prints). These methods are ideal for continuous paper rolls.

- Edge Alignment: Make sure that the design is aligned correctly on the roll, especially if its being printed continuously. Incorrect alignment could result in skewed prints or inconsistent branding.

- Repeatability: Test the repeatability of the logo design across long lengths. Make sure that the design remains sharp and consistent across the entire roll without pixelation or fading.

7. Finishing and Handling:

- Coating Effects: After printing, the one-side coated paper may be treated to provide extra durability or special effects like gloss or matte lamination. This ensures that the printed logo remains vibrant and protected throughout its use.

- Cutting: If the paper will be cut into specific lengths (e.g., for packaging or labels), make sure the edges are clean and theres no damage to the printed logo during the cutting process.

Example Use Case for Continuously Printed One-Side Coated Paper:

Lets say the design is for branded wrapping paper:

- Logo Design: A minimalistic, bold logo with clear, large typography in black and a splash of brand color (e.g., gold). This ensures that the logo is visible and impactful even on a matte background.

- Layout: The logo could repeat every 6-8 inches along the roll to create a consistent branding experience as the paper is used to wrap multiple items.

- Paper Characteristics: The one-side coated paper ensures that the wrapping is protected from water, oils, or tears, maintaining the integrity of the product inside.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

+91

Email

சிலிக்கான் பூசப்பட்ட காகிதம் உள்ள பிற தயாரிப்புகள்

|

G K ENTERPRISE

அனைத்து உரிமைகளும் பாதுகாக்கப்பட்டவை.(பயன்பாட்டு விதிமுறைகளை) இன்ஃபோகாம் நெட்வொர்க் பிரைவேட் லிமிடெட் . உருவாக்கப்பட்டது மற்றும் நிர்வகிக்கப்படுகிறது |

விசாரணையை அனுப்பு

விசாரணையை அனுப்பு